Medical solenoid valve

Medical solenoid valves are essential electromechanical devices in the healthcare sector, designed to control the flow of liquids and gases in medical and laboratory equipment with extreme precision. Made with specific materials to ensure hygiene, safety and reliability, these valves play a fundamental role in patient care and diagnosis.

Medical solenoid valve operation

Medical solenoid valves manage the flow of fluids and gases through an electrically-activated solenoid, which allows automated opening or closing of the passage according to operational needs.

- Valve opening: When activated by the control device, the solenoid valve allows the passage of fluid or gas, ensuring precision and speed in administration or withdrawal.

- Valve closing: Once the operation is finished, the power supply is automatically interrupted and the valve closes, avoiding dispersion and contamination.

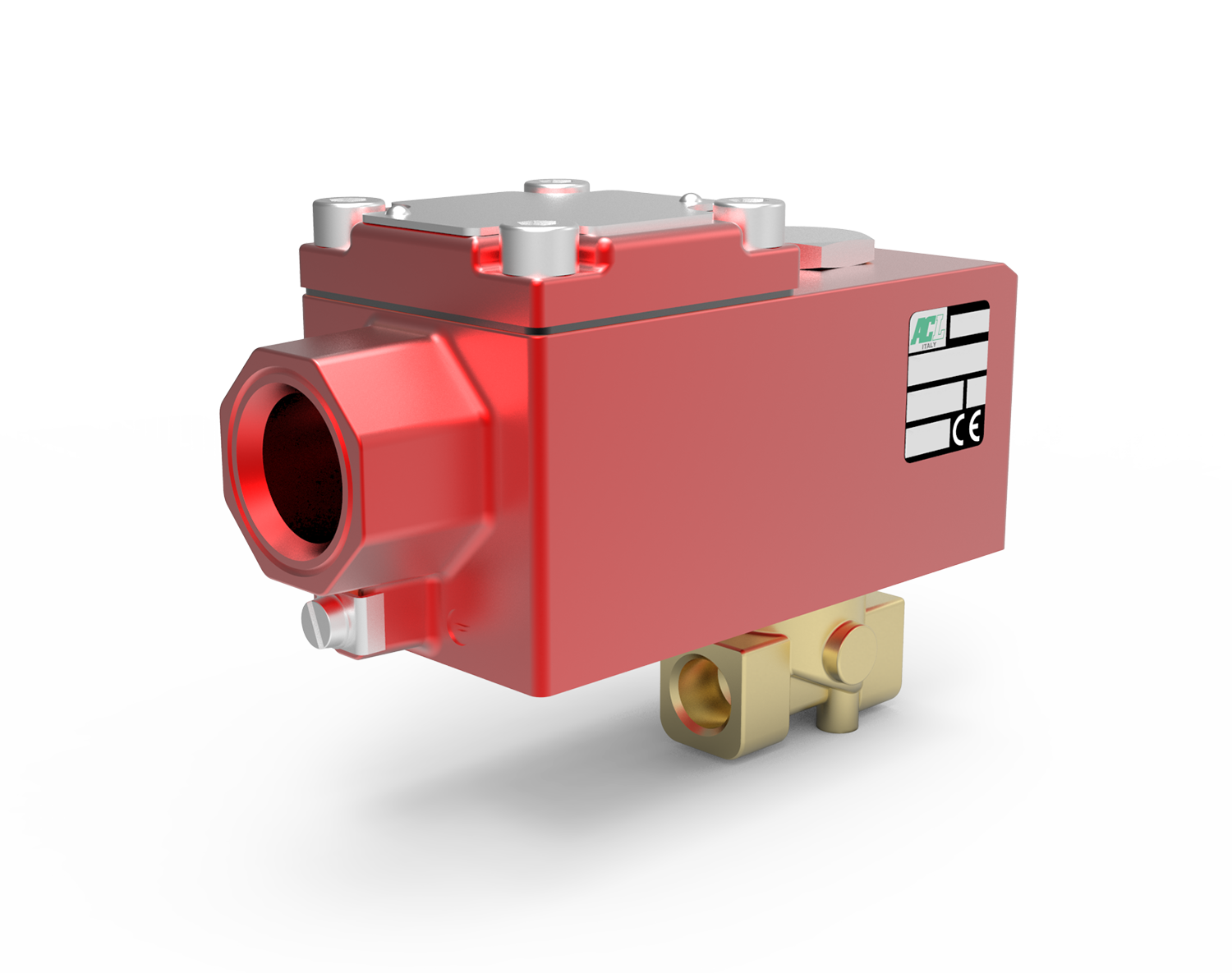

Our medical solenoid valves

Technical features

Certified materials:

Use of medical stainless steel, lead-free brass and biocompatible technopolymers compliant with international health standards.

Sterilisability:

Designed to withstand high temperature sterilisation processes and chemical methods.

Adjustment precision:

Available in monostable and proportional configurations, for accurate flow control.

Specific connections:

Threaded, quick connection or customisable to easily integrate with different medical equipment.

Applications

Dialysis equipment:

Regulation of fluid flow during kidney treatments.

Mechanical ventilation:

Precise control of respiratory gases in ventilators and anaesthetic equipment.

Laboratory diagnostics:

Accurate fluid management in analysers and diagnostic tools.

Surgical instruments:

Pressure and flow control in surgical and endoscopic equipment.

Drug administration:

Dosing and precise administration of therapeutic liquids in automated infusion systems.

Advantages

Utmost reliability:

Rigorous testing ensures consistent performance and high durability.

Guaranteed safety:

Designed to avoid contamination and ensure hygiene in critical contexts.

Reduced operating times:

Quick and precise operation for timely and efficient interventions.

Minimum maintenance:

The sturdiness of the materials and advanced design significantly reduce routine maintenance.