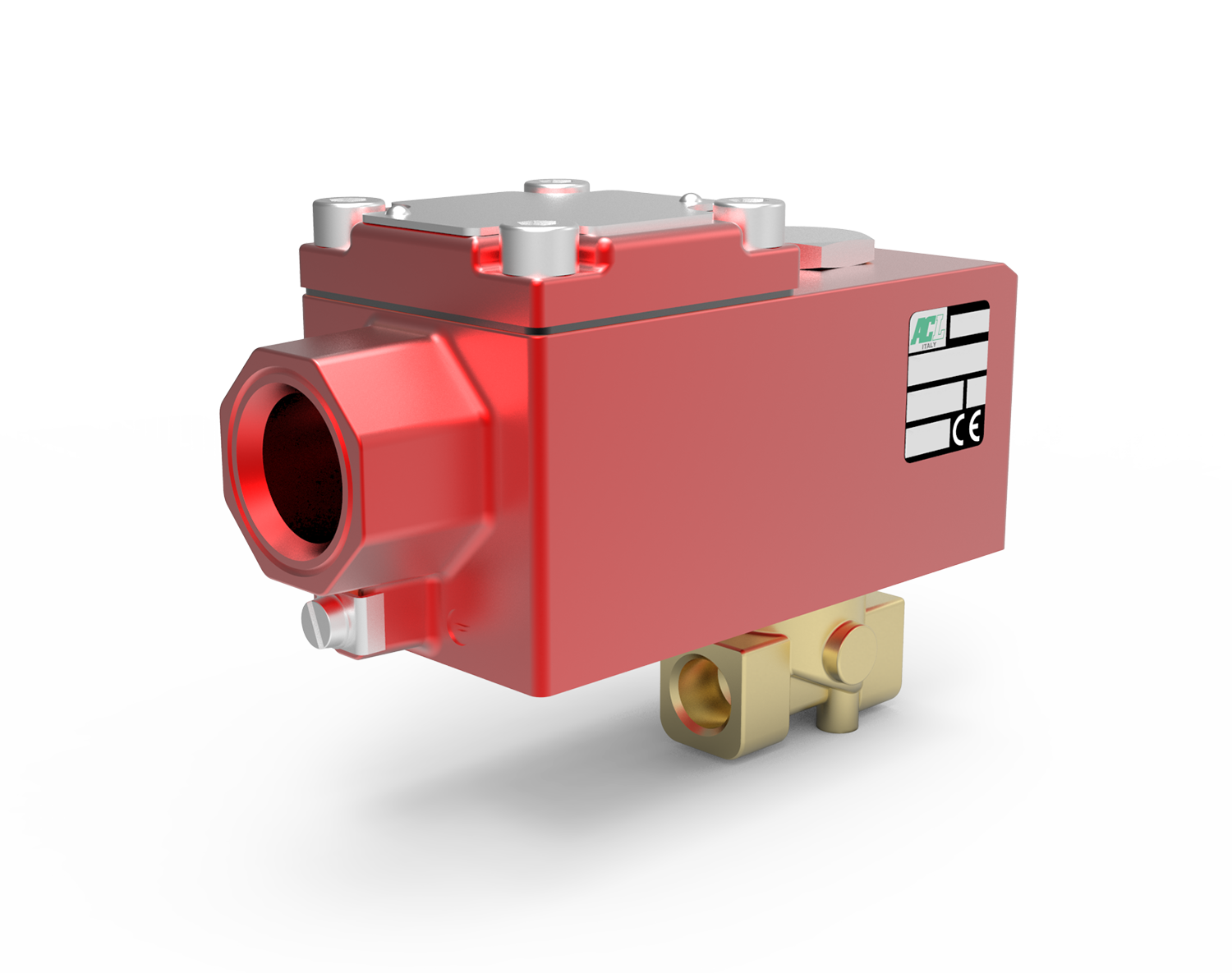

Compressed air solenoid valve

Compressed air solenoid valves are essential components that precisely regulate air passage and pressure in industrial pneumatic systems and domestic applications. Designed to offer maximum reliability and durability, ACL valves guarantee high and consistent performance in all operating conditions.

Air solenoid valve operation

Compressed air solenoid valves are electromechanical devices that manage the flow of air thanks to the activation of a solenoid.

- Circuit opening: when the solenoid is powered, it creates a magnetic field that lifts an inner core, allowing compressed air to flow through the valve.

- Circuit closing: when the power supply stops, the valve returns to the closed position, interrupting the air flow and keeping the pneumatic system under pressure.

Our compressed air solenoid valves

Technical features

Durable materials:

brass, stainless steel and high mechanical strength technopolymers.

Operating pressure:

they support low, medium and high pressures, with operating ranges up to several hundred bar.

Type of action:

available in a monostable, bistable and proportional version for flexible and precise adjustment.

Versatile connections:

threaded, quick or flanged, for easy installation and integration in each system.

Applications

Industrial automation:

precise control of pneumatic systems used in production lines, robotic handling and general automation.

Industrial machinery:

air flow management in presses, pneumatic equipment and assembly machinery.

Automotive sector:

use in air suspension, braking and air conditioning systems.

Medical and health:

control of pressure and air flow in medical and diagnostic equipment.

Air and fluid treatment:

precise and safe management of filtration and compressed air treatment systems.

Advantages of compressed air solenoid valves

High reliability:

components tested to ensure optimal performance in harsh environments and harsh operating conditions.

Operational precision:

accurate control of flow and pressure, for optimal management of pneumatic energy.

Low maintenance:

robust structure that minimises maintenance and guarantees durability.

Guaranteed safety:

designed to prevent leaks and malfunctions, ensuring operational safety in any context.