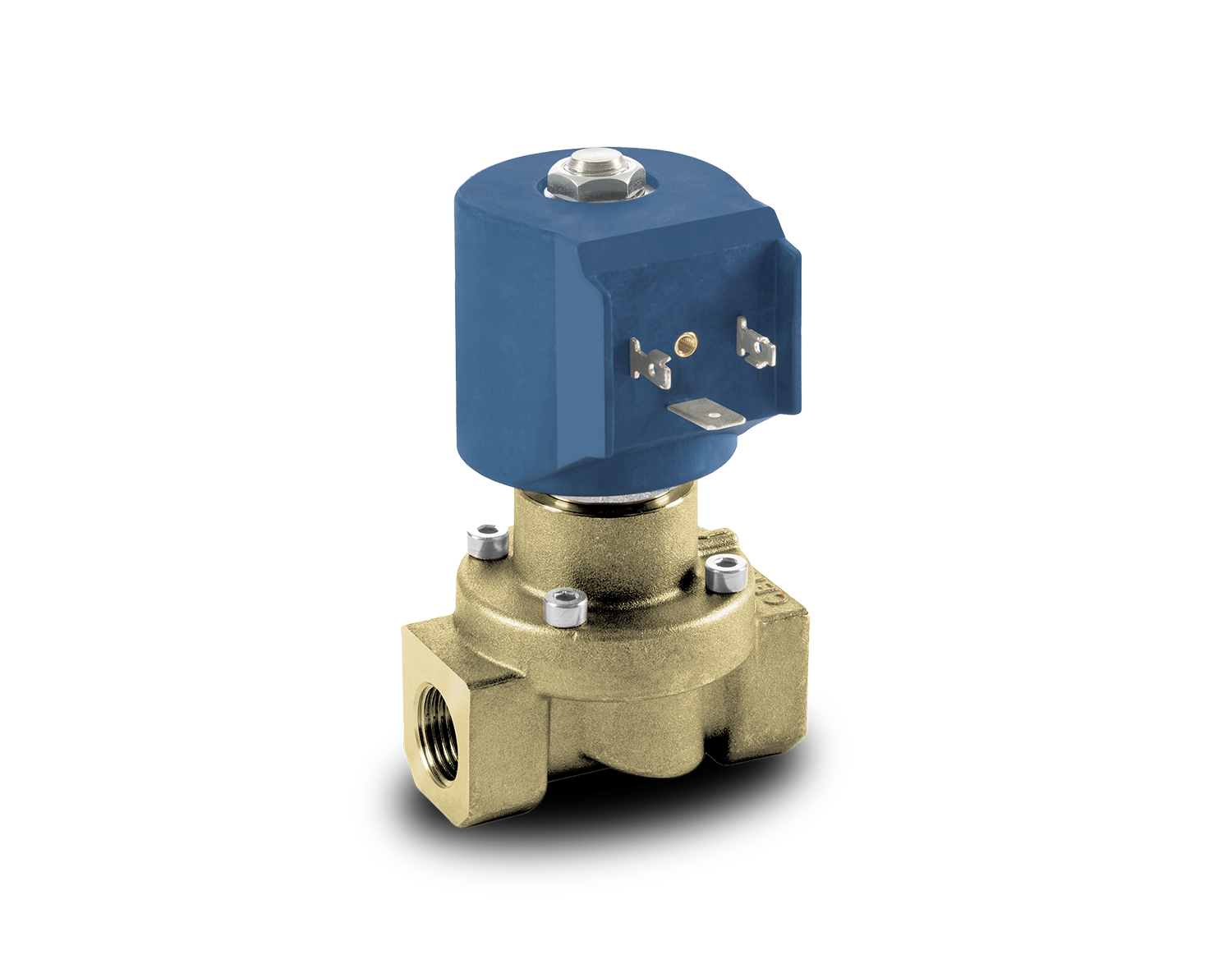

Steam Valve

Air valves are essential components for controlling the flow of air and gas in numerous industrial and domestic systems. These devices ensure safety, efficiency, and precision in the operation of pneumatic systems, ventilation circuits, and air conditioning systems. Let's explore how they work, their types, and their main applications.

Air valve operation

An air valve regulates the flow of air or other gases through a circuit, allowing or interrupting the flow according to the system’s needs. These valves can operate manually, mechanically, pneumatically, or electronically, depending on the application’s needs.

- Opening the circuit: The valve allows air to pass through the system when activated.

- Closing the circuit: The flow is interrupted to maintain pressure and prevent leaks.

- Flow regulation: In some configurations, the valve allows gradual adjustment of air inlet and outlet.

Our steam valves

Types of Air Valves

Shut-off valves:

These valves allow air to be stopped or allowed to flow through a circuit.

Regulator valves:

These valves allow precise control of air flow to optimize system performance.

Safety valves:

Designed to vent excess air and prevent overpressure.

Bleed valves:

These valves eliminate trapped air in hydraulic or pneumatic circuits.

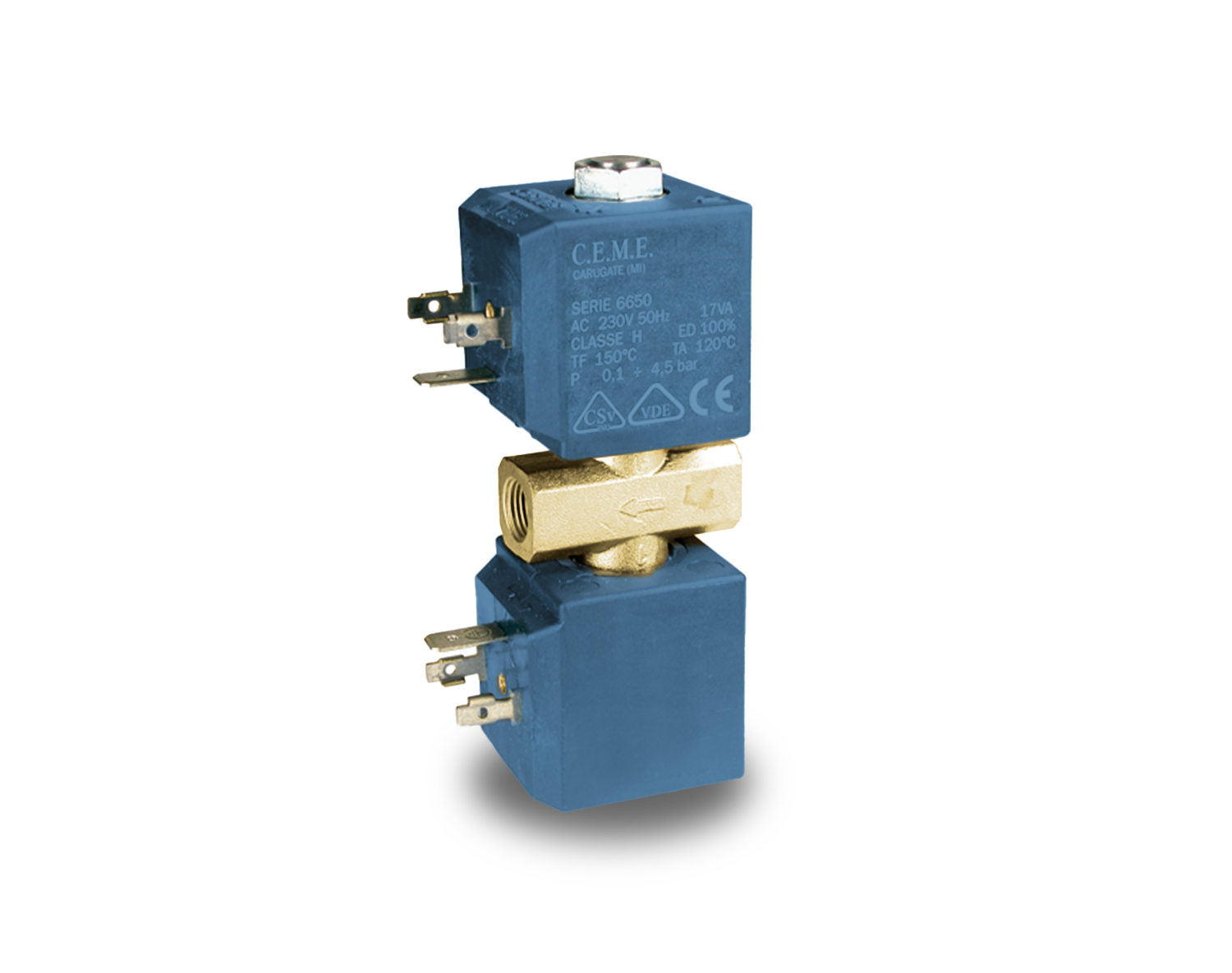

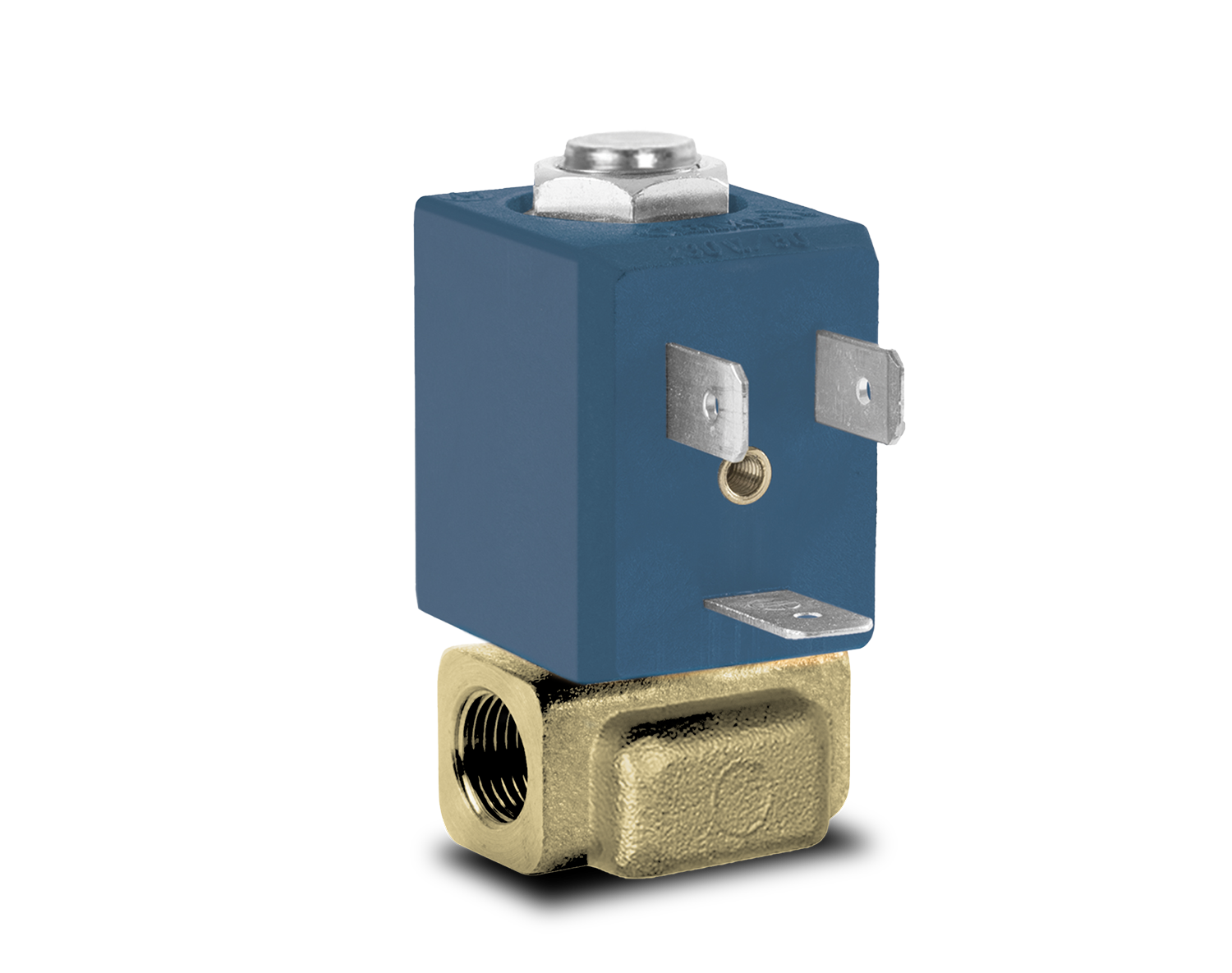

Solenoid valves:

Electrically activated, they offer automated flow control.

Butterfly valves:

Used to regulate large volumes of air in HVAC and industrial systems.

Applications of Air Valves

Automotive Industry:

Air regulation in engines, air conditioning systems, and pneumatic brakes.

HVAC (Heating, Ventilation, and Air Conditioning) Systems:

Air flow control in ventilation and air conditioning systems.

Industrial Automation:

Compressed air management for the operation of pneumatic actuators.

Air Treatment Machinery:

Regulation in air purification and filtration systems.

Medical Sector:

Air control in breathing and oxygen delivery devices.

Purification Systems:

Use in aeration and fluid treatment.