Steam safety valve

Steam safety valves are essential components for ensuring the proper operation and safety of industrial and domestic systems. These devices prevent overpressure that could compromise the integrity of the system, protecting equipment and operators.

Steam safety valve operation

Steam safety valves operate through an automatic mechanism that releases excess pressure when it exceeds a pre-set limit. The heart of the system is a calibrated spring that keeps the valve closed until the pressure returns to the safety parameters.

When the limit is exceeded, the valve opens, allowing the excess steam to be released, preventing damage to the systems and ensuring optimal operation.

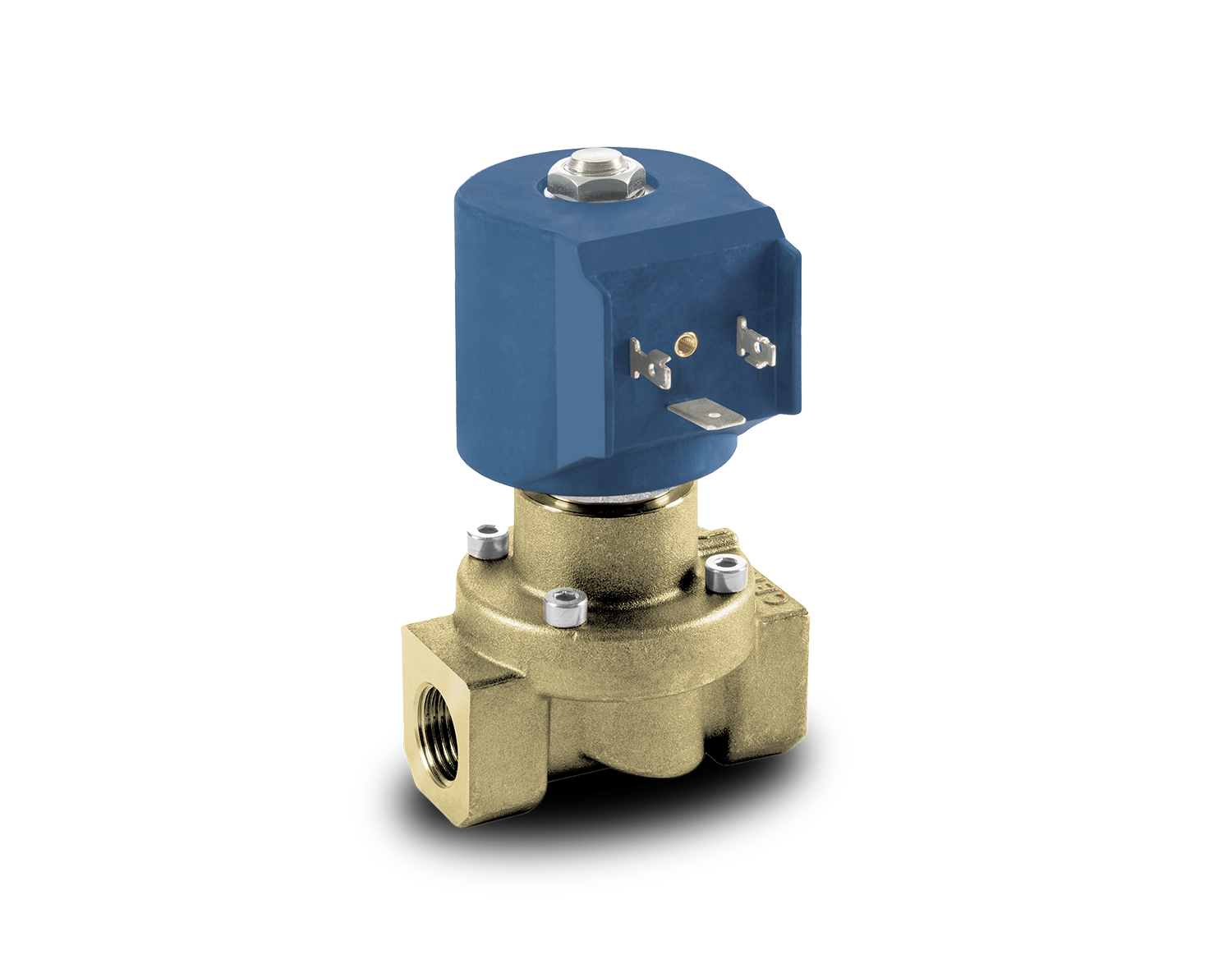

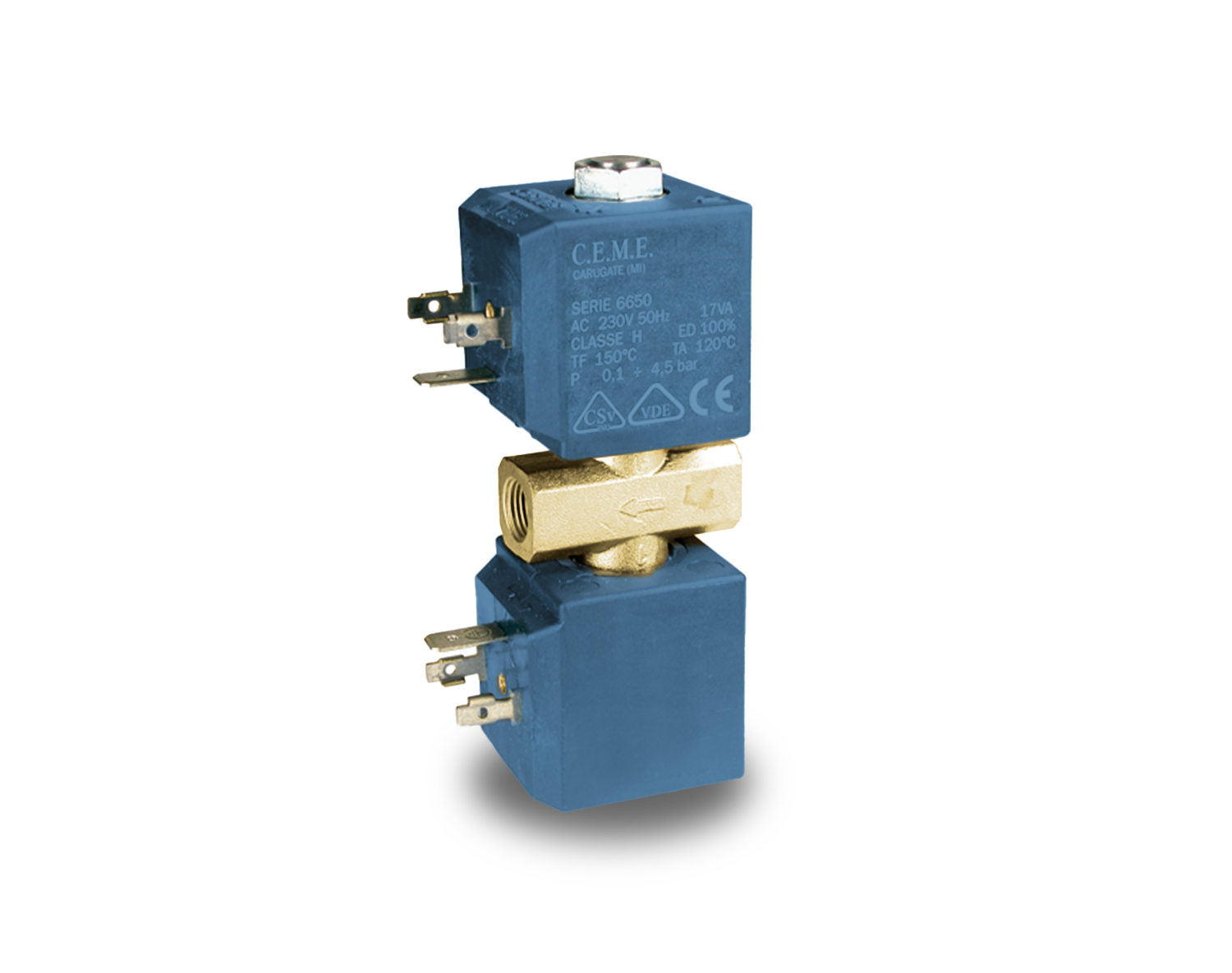

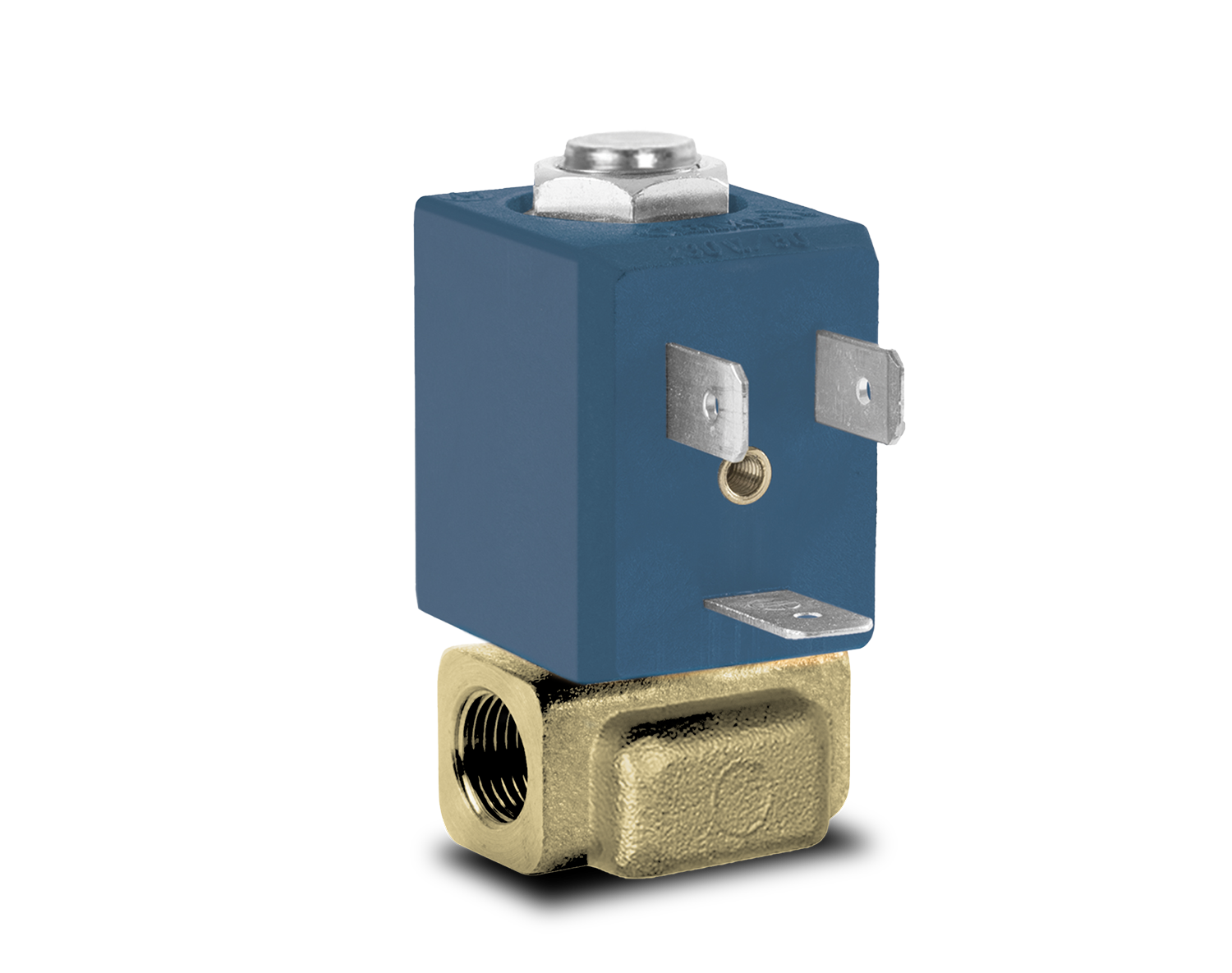

Our steam safety valves

Types of Steam Safety Valves

Spring-operated valves:

The most common, featuring a calibrated spring that determines the opening pressure.

Pilot-operated valves:

Offer more precise control of pressure release, ideal for complex systems.

Free-vent valves:

Allow steam to be released directly into the environment.

Piped-vent valves:

Redirect steam into a dedicated circuit to prevent unwanted leaks.

Applications of Steam Safety Valves

Heating and boiler systems:

Protection from overpressure in thermal systems.

Food industry:

Safety in steam cooking and sterilization processes.

Chemical and pharmaceutical industries:

Pressure control in reactors and production plants.

HVAC and air conditioning:

Pressure regulation in steam circuits for humidification and air treatment.

Industrial systems:

Pressure management in steam generation and distribution systems.

Benefits of Steam Safety Valves

Certified reliability:

Complies with international safety standards.

Precise pressure control:

Ensures gradual and effective steam release.

Durable materials:

Made of stainless steel and brass for maximum durability.

Easy installation and maintenance:

Designed for simple integration into existing systems.