Air solenoid valve _

Air solenoid valves are fundamental components for controlling the flow of compressed air in industrial and domestic systems. These devices ensure the effective management of gaseous fluids, optimising the performance of machinery and systems and improving energy efficiency.

Automotive valve operation

Air valves operate by regulating the passage of fluid through an automated opening and closing system.

The main mechanism makes use of an actuator, which can be pneumatic, electric or manual, to control the air flow in the circuit.

- Opening: the valve opens to allow compressed air or gas to pass into the system.

- Closing: once the desired pressure value is reached, the valve closes to prevent waste and keep the pressure stable.

- Flow regulation: some valves allow the regulation of the amount of air introduced into the system for a more precise control.

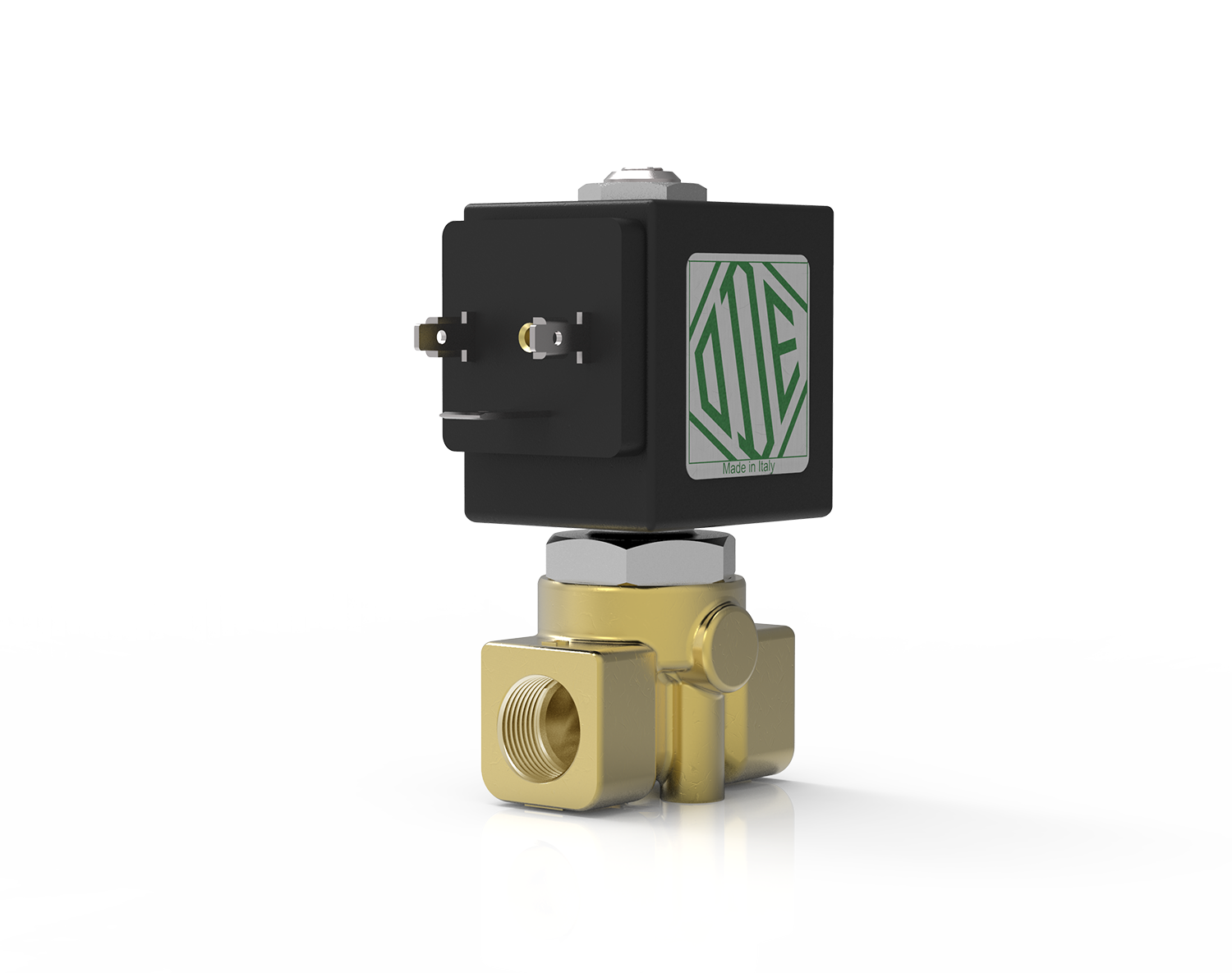

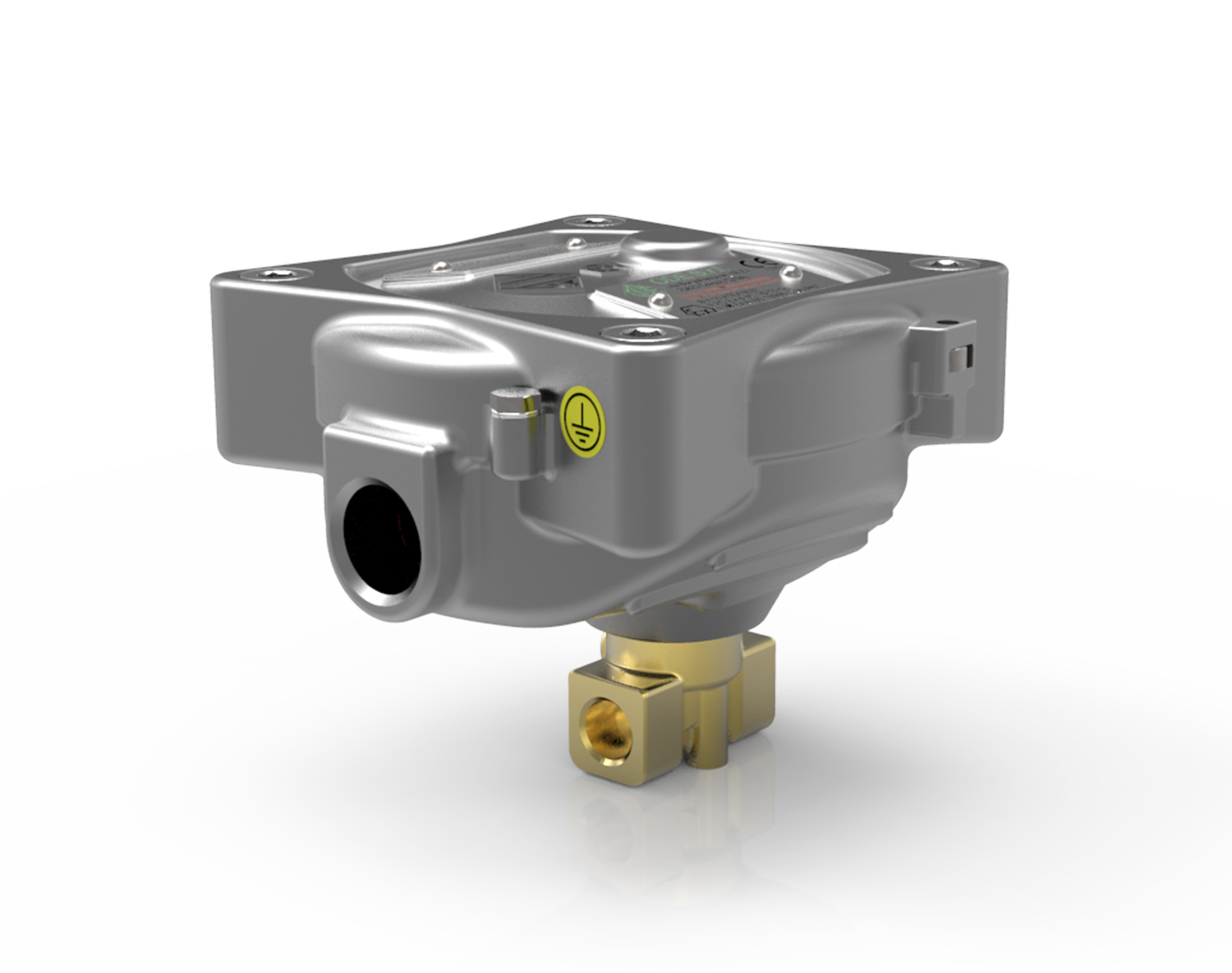

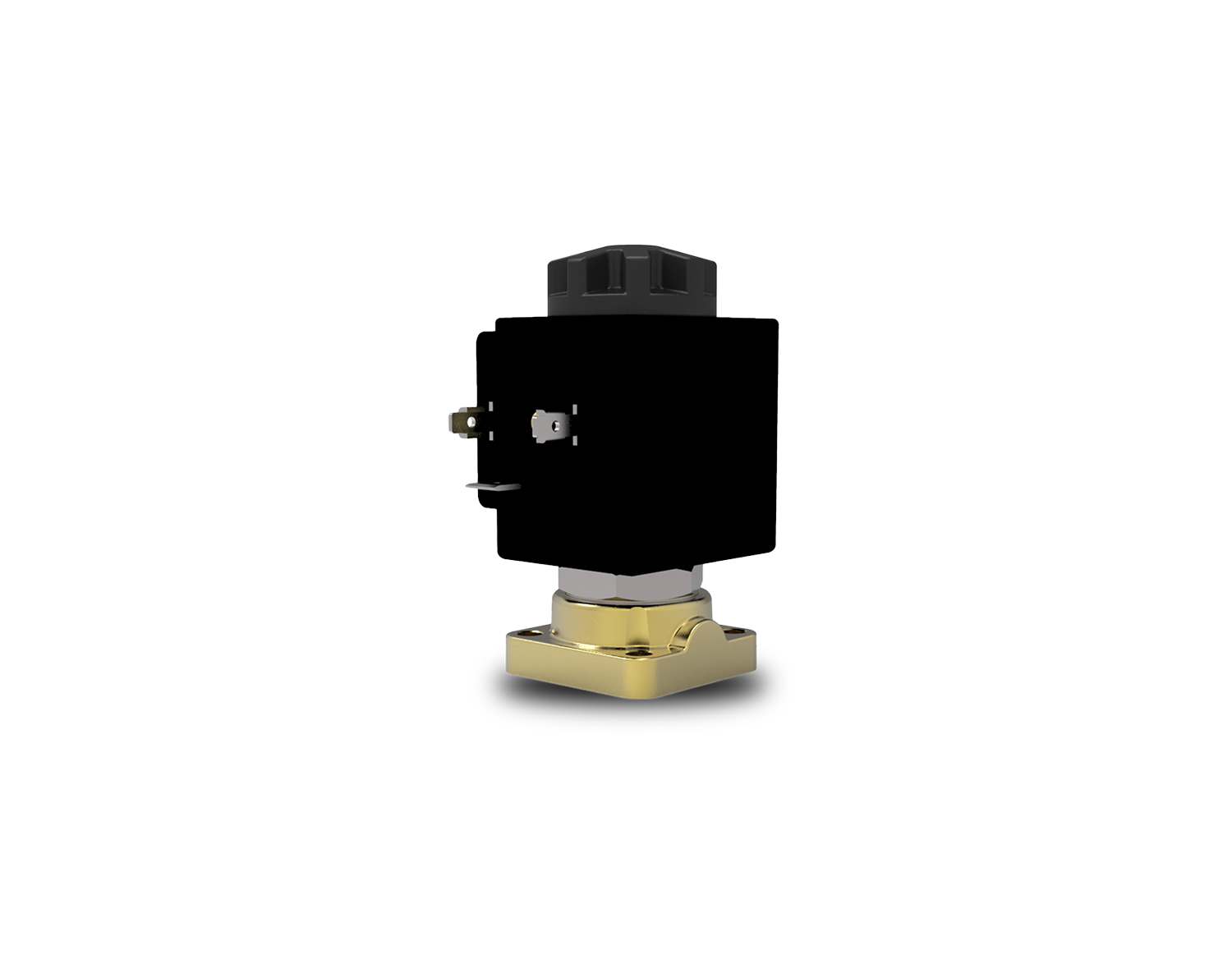

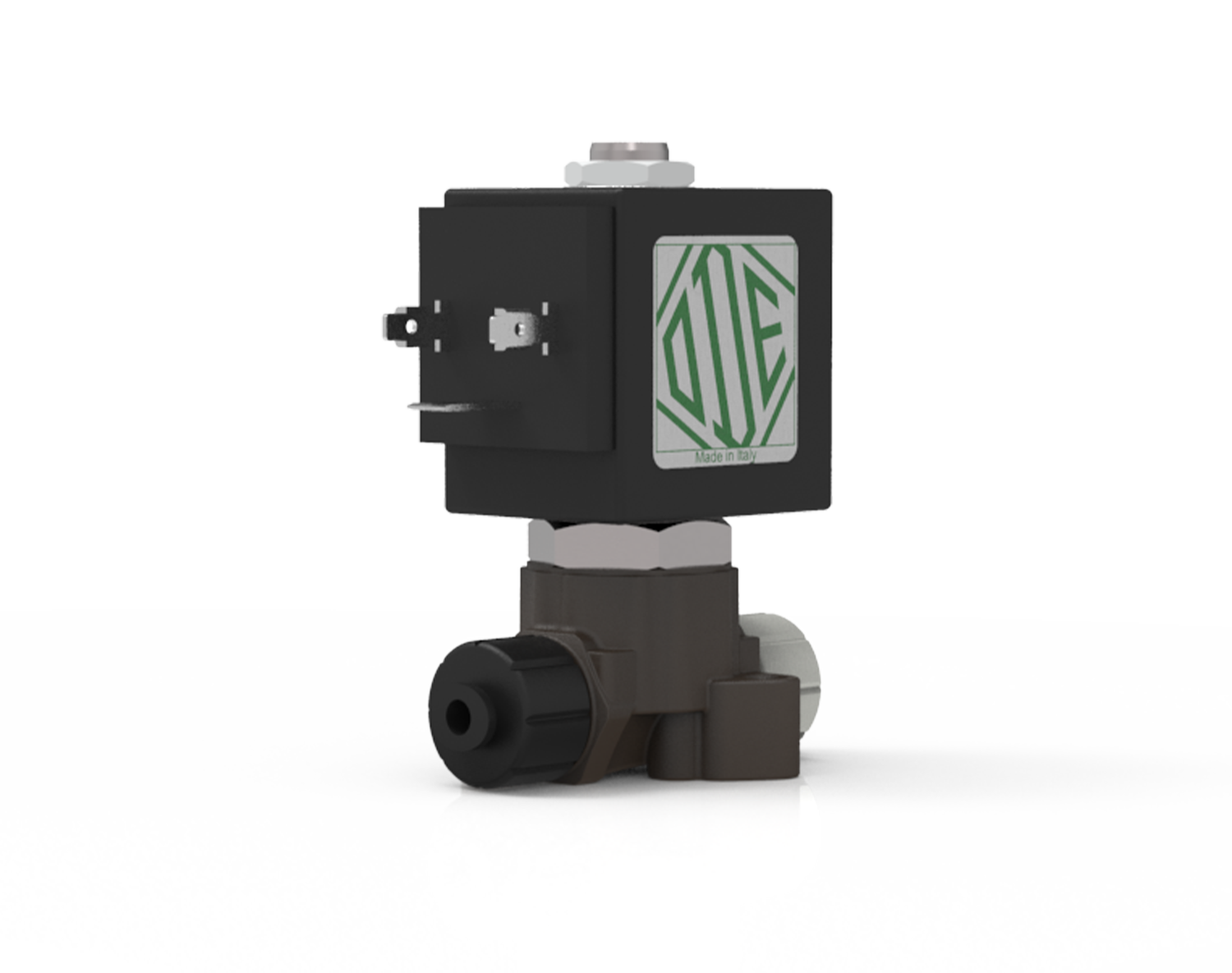

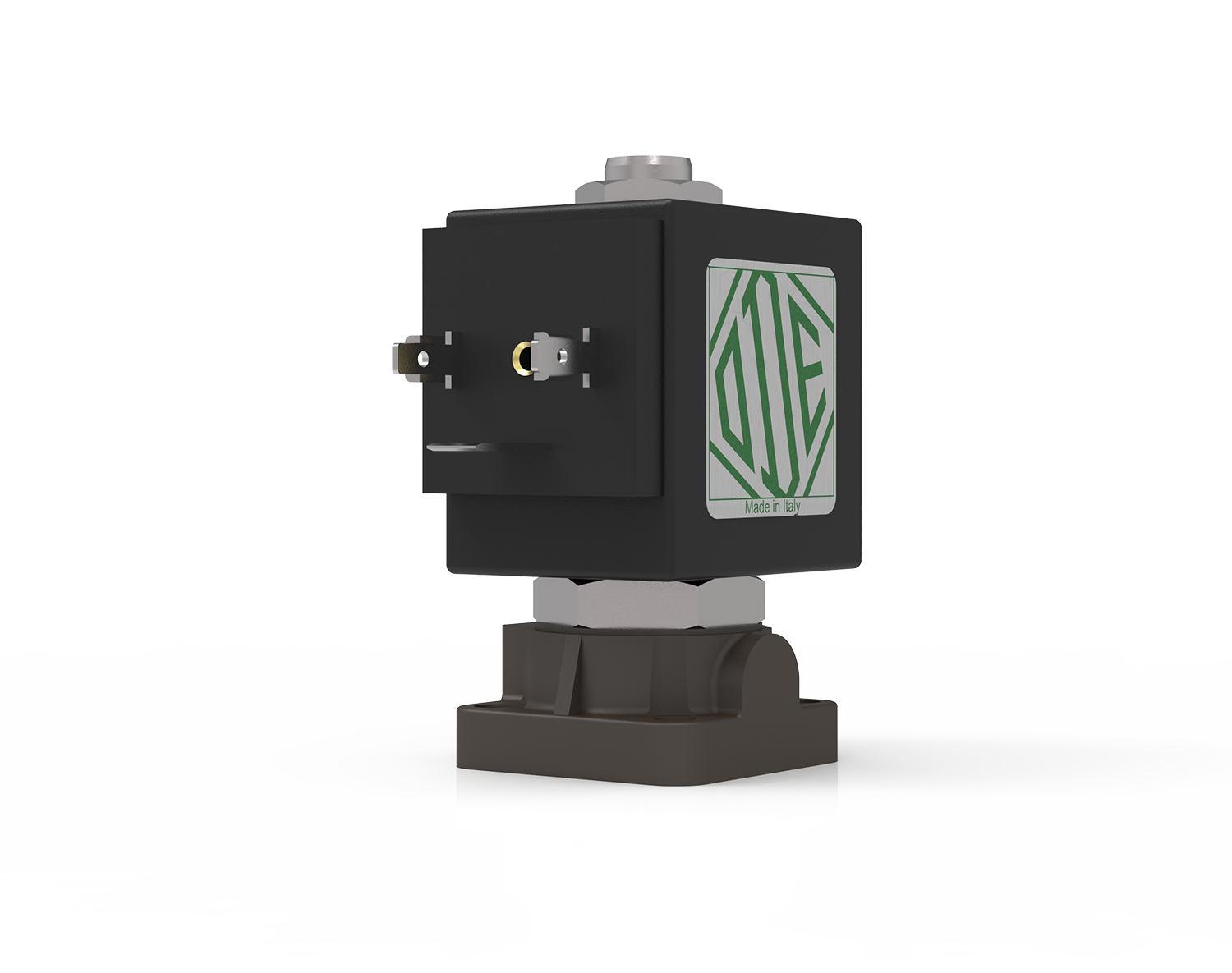

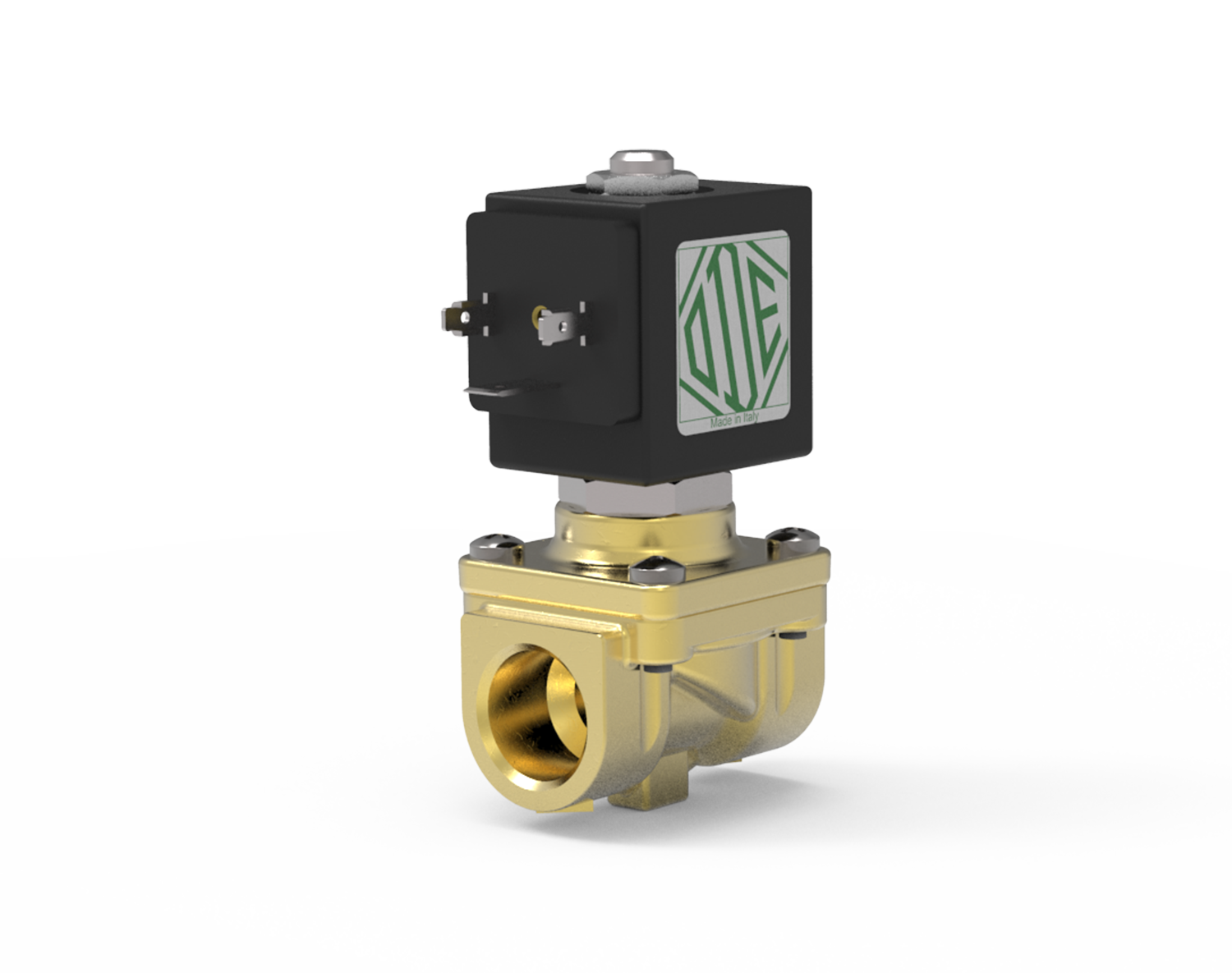

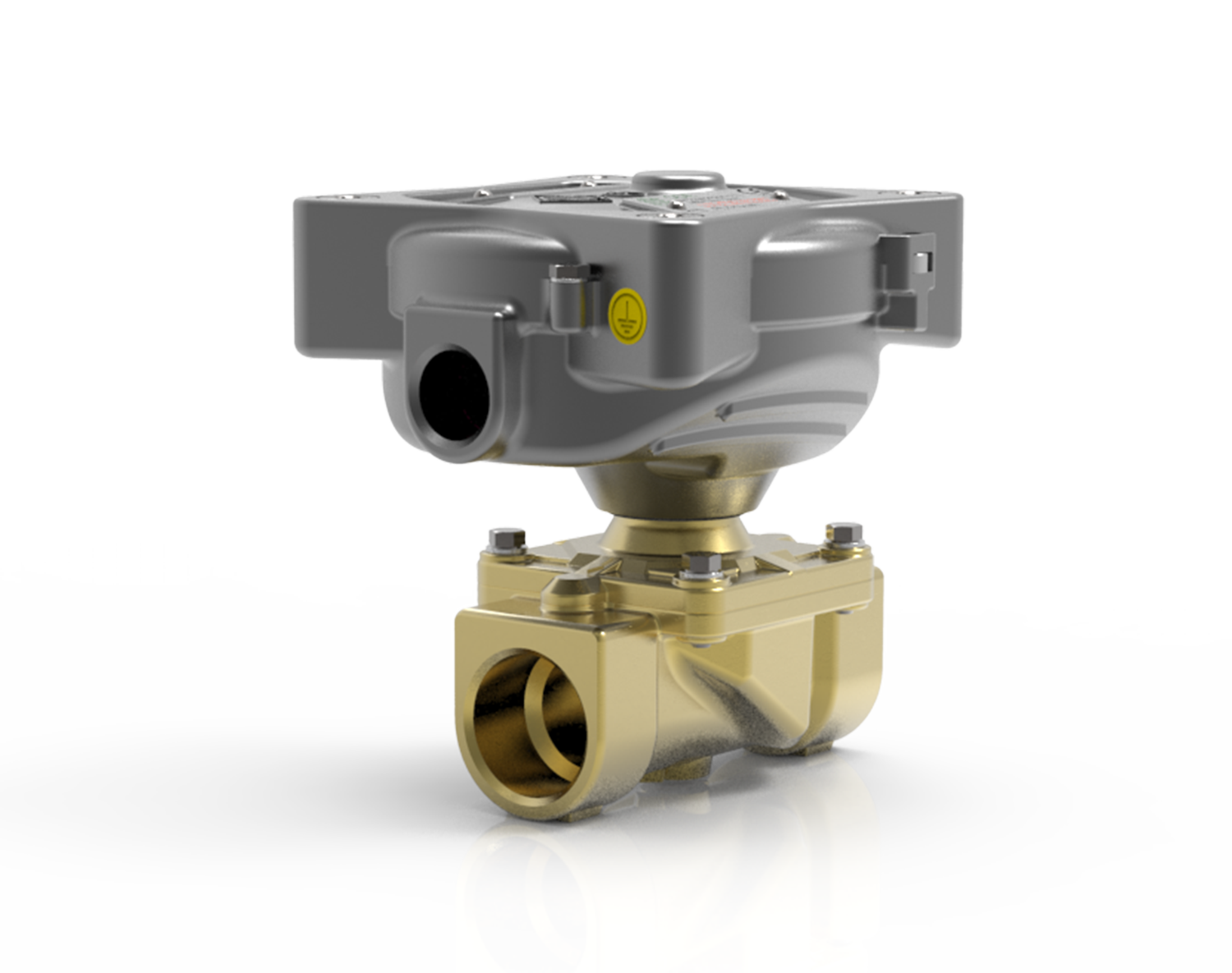

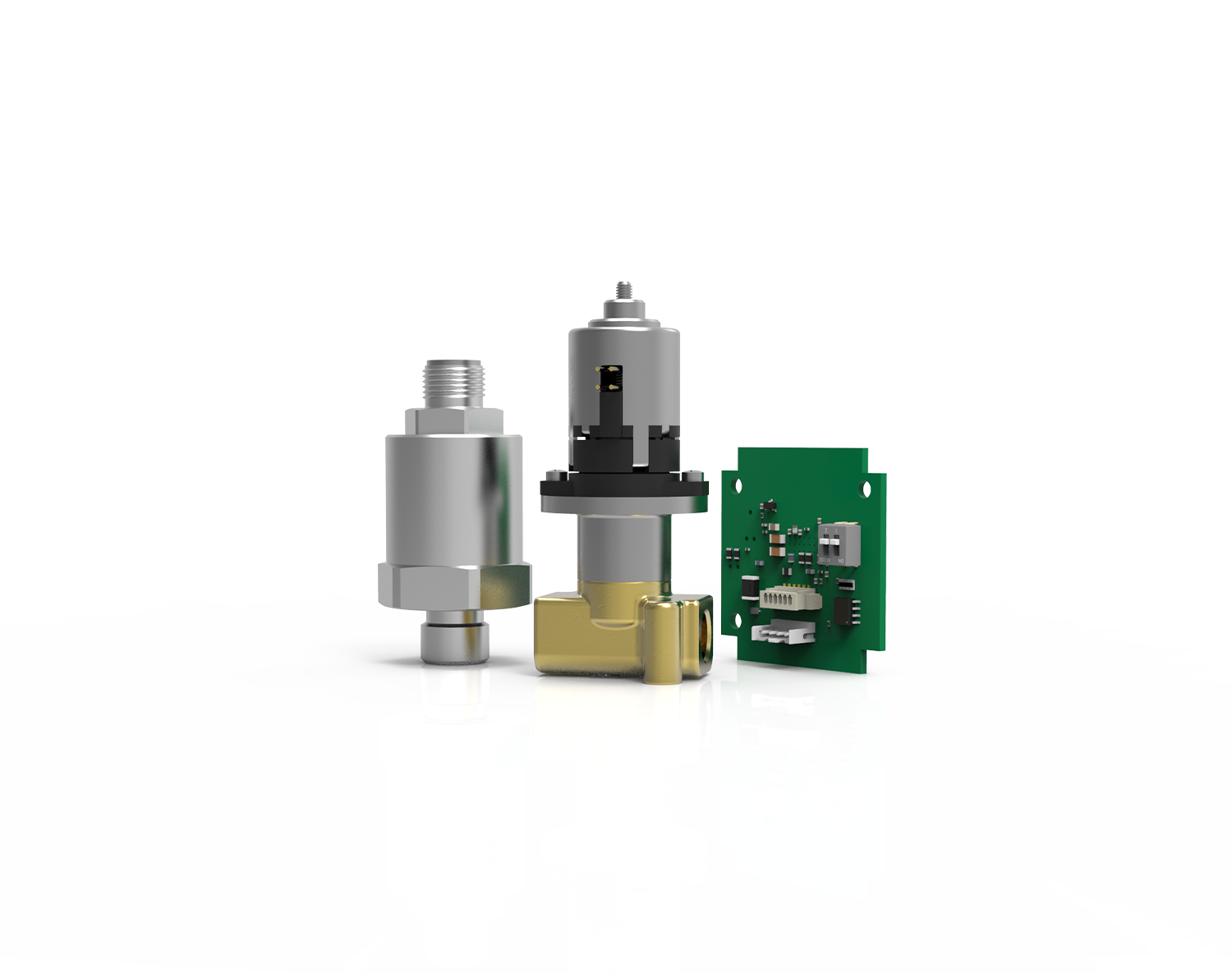

Our air solenoid valves

Types of air valves

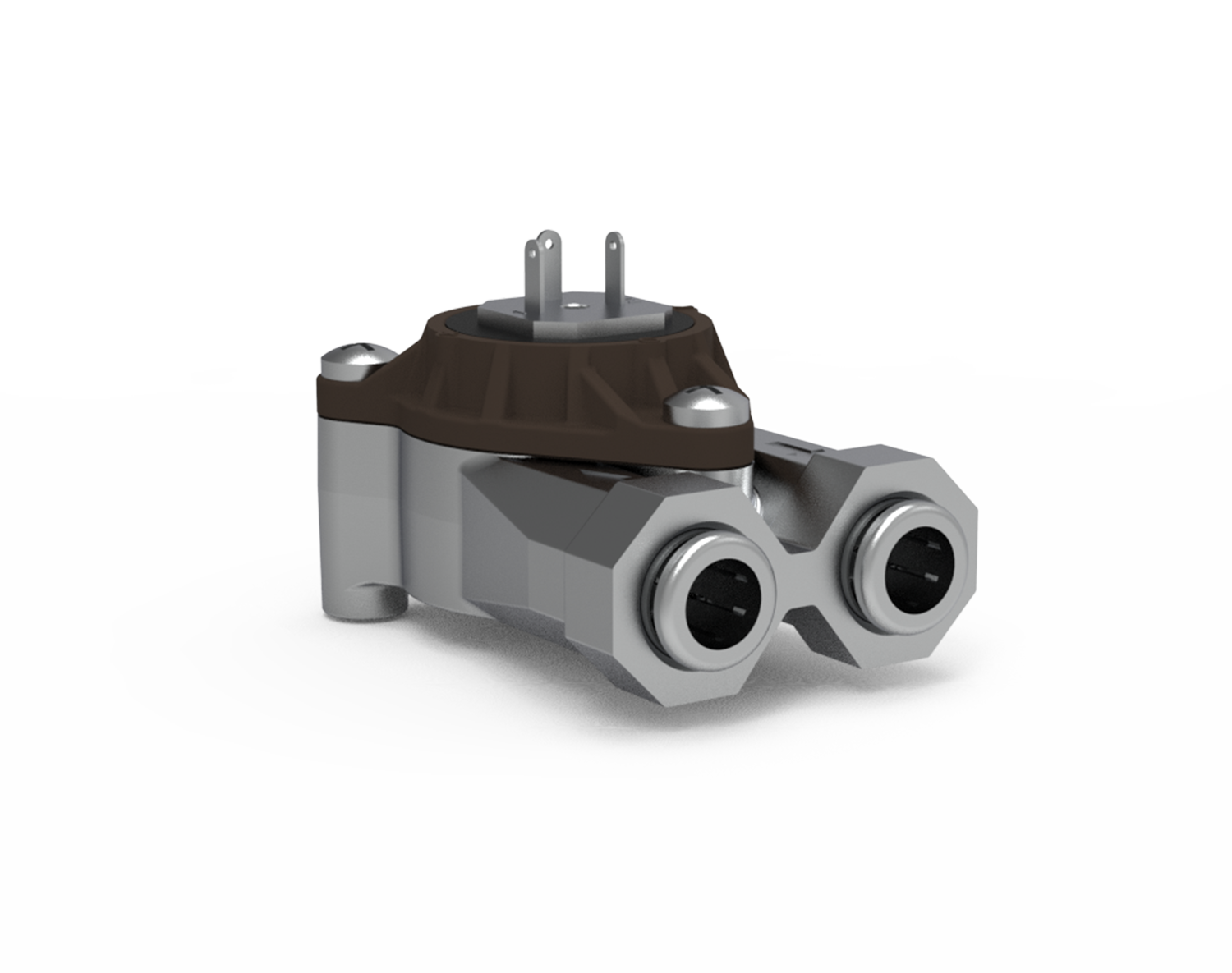

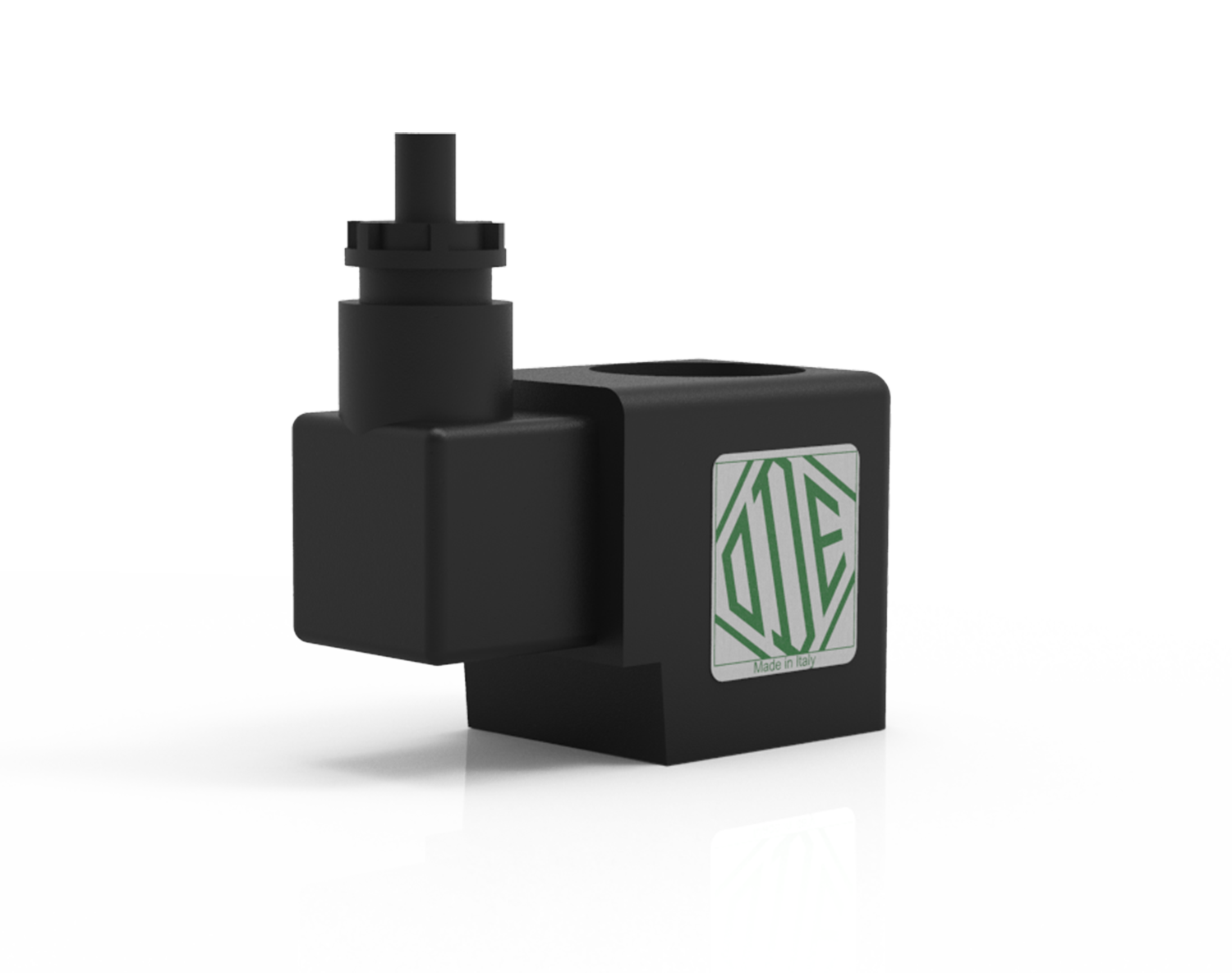

Solenoid valves:

electrically activated, they ensure fast and precise airflow control.

Butterfly valves:

used to adjust the flow rate, they allow you to modulate the air inlet.

Safety valves for compressed air:

designed to automatically release excess pressure and protect the system.

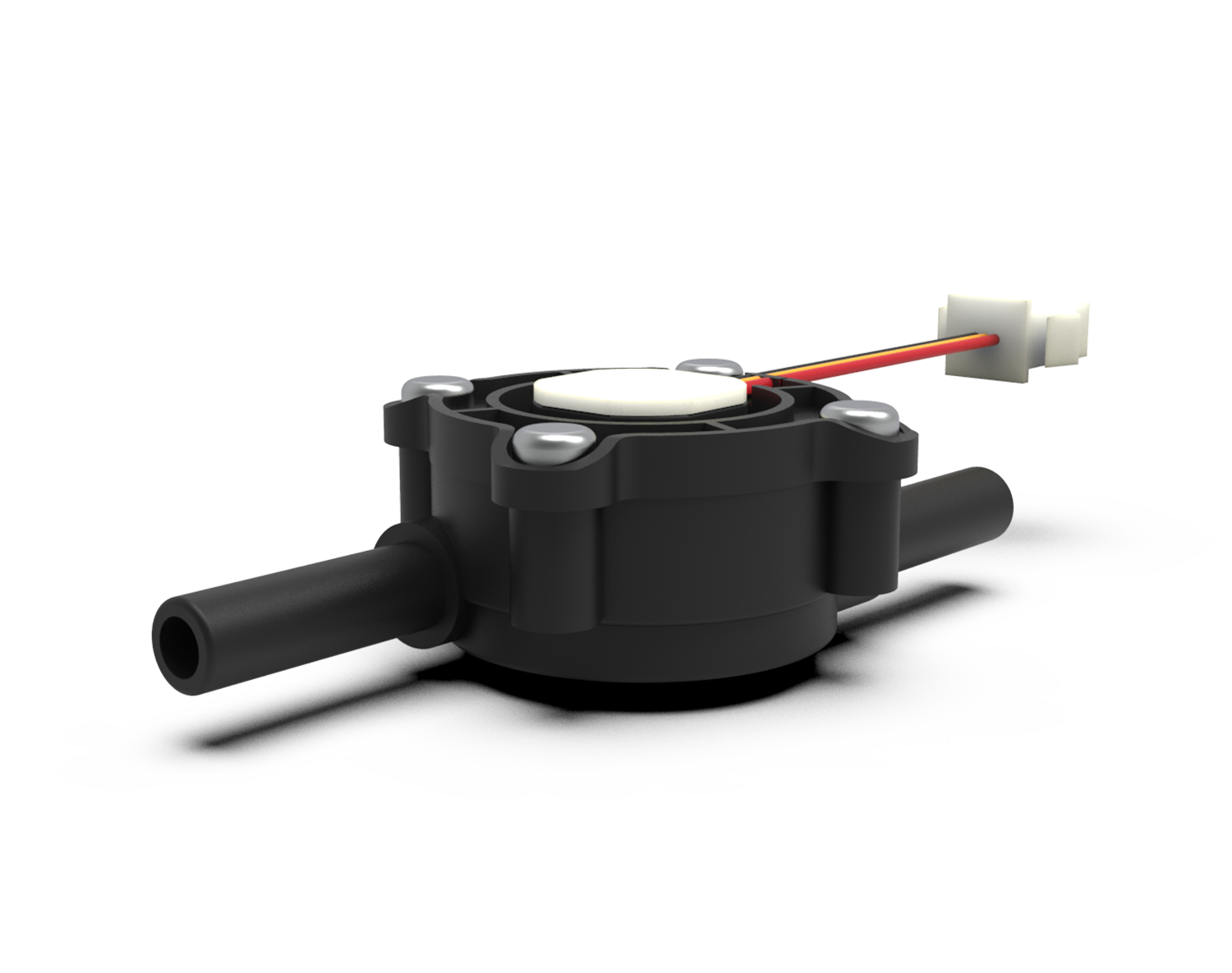

One-way (or non-return) valves:

allow the passage of air in only one direction, avoiding unwanted backflows.

Manual valves:

controlled directly by the operator, ideal for less automated applications.

Air valve applications

Industrial automation:

air control in pneumatic systems for production machinery.

HVAC and air conditioning:

air regulation in ventilation, air conditioning and heating systems.

Compressed air systems:

pressure management and air distribution in workshops and factories.

Medical sector:

control of medical gases in hospitals and laboratories.

Food industry:

use in packaging and product handling systems.

Transport and automotive:

airflow management in pneumatic systems of vehicles and trains.